The fundamental power behind Lean Manufacturing is in the visual keys, cues and instructions. Lean forces efficiency through the elimination of waste (wait time, wasted movement, mistakes and subsequent scrap) and in most cases the method for the elimination of waste is through visual cues on what to do next, where to go next or what NOT to do… The beauty of Lean Manufacturing is that it can be implemented effectively, efficiently and quite inexpensively with the right tools.

WAYFINDING

Efficiency in Lean Manufacturing is all about QUICK & CLEAR communications to your employees. Visual cues to employees can be accomplished in a number of ways from floor mounted to signs hanging from the ceiling, and everything in between!

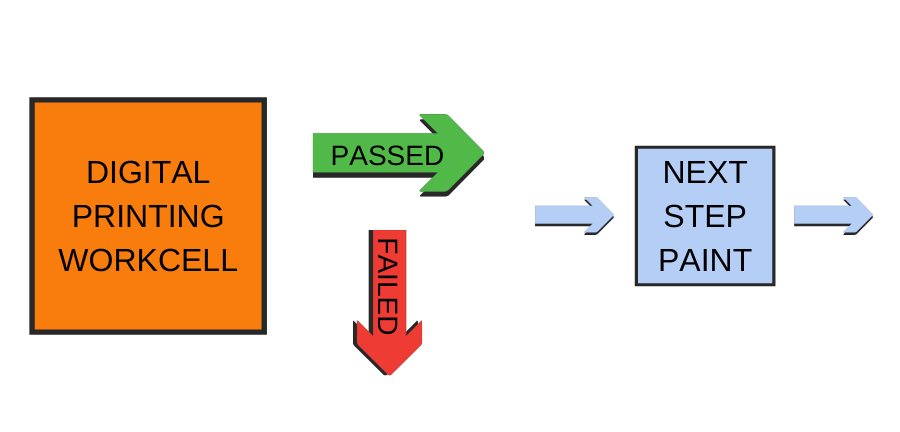

Visual identification of process direction (i.e. what is the next step) eliminates any hesitation regarding employees, especially new employees, in where to go next, what to do with good / bad material, etc…

SAFETY SIGNAGE

Safety signage is another type of Lean Manufacturing visual that eliminates hesitation. Proper signage ensures that an employee knows that PPE is required in a given area, social distancing is required or that a particular area has danger (high electricity, contaminated materials, etc…) Not only is this a method to reinforce the employees health and safety but it does so in an expedited manner.

POKA YOKE

Poka Yoke solutions are another very powerful tool in the Lean Toolbox. Poka Yoke is quite literally “mistake proofing” – it is a process step or a design change that eliminates the potential for human error. There are two primary ways to accomplish a Poka Yoke solution:

- Design based: Design based Poka Yoke is the more permanent solution BUT that solution comes at the cost of time in design and changes to an already released product. and In many industries those design changes must go through have to have customer review and approval. The other drawback to Design based Poka Yoke is in the cost to adjust as well once or if the original Poka Yoke design solution still produces errors.

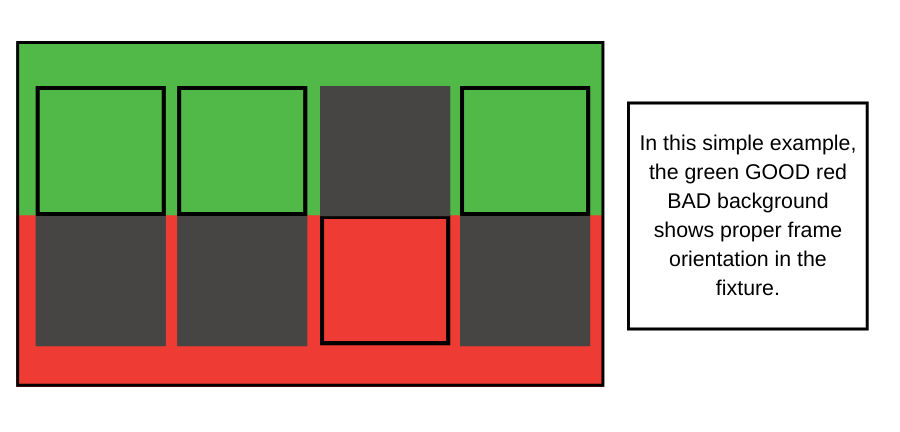

- Process based: Poka Yoke, like all of the Lean Tools relies on visual cues. and The beauty of these solutions is that they are often very inexpensive to accomplish, can be fool proof and in most cases there is no customer notification or approval required. For all of those reasons adjustments and tweaks are easier, faster and less costly.

One of the most underused tools in the Poka Yoke arena is plexiglass in all its forms. Plexi is easy to cut, easy to mold and carve and holds vinyl very well for Poka Yoke color options. Another underutilized aspect of Poka Yoke and plexiglass is LIGHT! Most plexi is clear so light fixturing can be applied to the back to allow for a much clearer visual error detection.

The creative application of visual cues and signage is a powerful tool in your Lean Toolbox. Guiding employees in what to do next, what NOT to do next and how to protect themselves from harm can be quickly and accurately accomplished with the right signage or visual marks.

Learn more about manufacturing facility signage.

Contact Elevated Sign Solutions for assistance with your Lean implementation.

Leave A Comment